Supplier of Copper Cathodes

High-Quality Solutions for Your Business Needs

We are a leading global supplier of copper cathodes from the Democratic Republic of Congo. Our copper is delivered directly to renowned refiners, smelters, fabricators, and manufacturers worldwide, who process these raw materials into essential copper products that play a vital role in the daily lives of consumers globally.

We offer high-quality copper cathodes, grade A, with purity ranging from 99.7% to 99.99%, free from impurities such as copper sulfate, dirt, grease, and oil. Our products are primarily supplied on a long-term basis, leveraging Tamasha’s expertise in securing reliable, ongoing sources. This ensures that our clients worldwide benefit from consistent, cost-effective copper cathode supplies from Africa.

We invite prospective buyers to visit us in Tanzania to explore opportunities for establishing a successful, long-term business partnership.

Our copper cathodes are highly sought after for their superior purity, durability, and versatility, making them ideal for various industrial applications. Whether you’re looking for a supplier of copper cathodes for electrical manufacturing, or construction purposes, we provide solutions tailored to your needs.

Company profile

Name: Tamasha Mining Company

Location: Number 46, Streeniat Mbezi Beach Makunde, Dar Es Salaam – Tanzania

Whatsapp: +255 767 647 642

Port of origion: Dar es Salam

Monthly supply ability: 10,000 tons

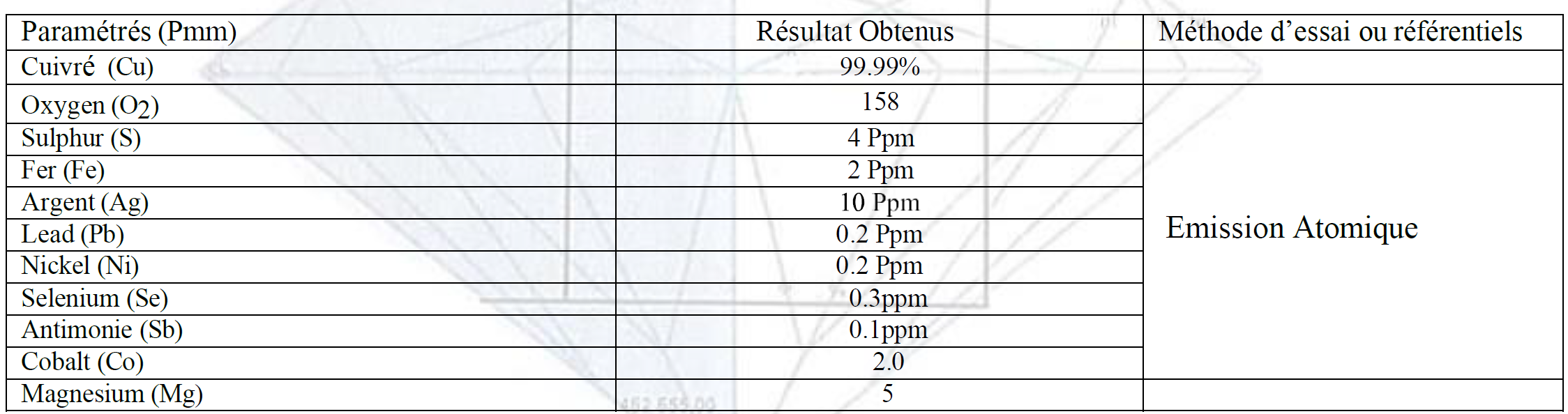

Specifications of Our Copper Cathodes

Below is a detailed breakdown of our product specifications:

Industry-Specific Attributes:

Overview

| Dimension | 914mm x 914 x 12mm (appr.) (+/-1%) (LME Standard) |

|---|---|

| Weight of each sheet | 125kgs (+/- 1%) |

| Net weight of each pallet | 2mts (+/- 1%) |

| Min. weight in each container | 20 mts approx. |

| Gross weight of each container | 22.20 mts approx |

| Copper (Cu) min% | 99.99%-99.97% min |

Benefits of Our Copper Cathodes

1. Versatile Applications

Our copper cathodes are ideal for:

- Electrical wiring: Exceptional conductivity and durability.

- Manufacturing: Production of pipes, plates, and wires.

- Construction: Roofing, plumbing, and architectural features.

- Automotive Industry: Essential for electrical and thermal components.

2. Environmentally Sustainable Production

By partnering with recyclers in China, we contribute to reducing environmental impact, making our copper cathodes an eco-friendly choice.

3. Enhanced Productivity

High-purity copper ensures superior performance in all applications, reducing downtime and maintenance costs.

Why Choose Tamasha Group as your supplier of copper cathodes?

1. High-Quality Copper Cathodes for Sale

Our copper cathode boast a remarkable purity level of 99.9%, ensuring reliability in even the most demanding applications. Manufactured by renowned facilities in the 2nd exporter of copper cathodes in world (Congo), our products meet international quality standards.

2. Reliable Copper Cathode Suppliers

As one of the top suppliers of copper cathodes in Tanzania, we pride ourselves on delivering excellence. From sourcing to packaging, every step of our process is meticulously managed to ensure customer satisfaction.

3. Comprehensive Global Reach

We cater to a wide network of copper cathode importers in regions like:

- South Korea

- Japan

- European Union

- United States

4. Competitive Pricing

Our partnerships with leading manufacturers and recyclers allow us to offer copper cathodes for sale at highly competitive rates.

Application of Copper Cathodes.

Copper cathodes are a critical raw material in the production of a wide array of copper-based products used in various industries. These cathodes, typically manufactured in dimensions ranging from 0.5 m² to 1 m² and thicknesses between 3 mm and 20 mm, serve as the foundation for producing copper rod for the wire and cable sector, as well as other essential copper products such as brass, copper tubes, sheets, and a variety of alloys—over 450 in total.

As a primary source of high-purity copper, cathodes play an essential role in the creation of copper alloy products. It is vital that during their transport and shipping, copper cathodes remain uncontaminated by foreign materials to maintain the integrity of their quality.

The Copper Production Process: From Ore to Finished Product

Copper’s journey from raw material to finished product involves several key stages. Whether sourced from mined ores or recycled materials, copper undergoes various processes that transform it into the high-purity metal used in a wide range of applications. Below is a detailed overview of the copper production process:

1. Mining and Crushing

Copper production begins with the extraction of sulfide and oxide ores through methods like digging and blasting. These ores are then crushed into walnut-sized pieces, ready for further processing.

2. Grinding

The crushed ore is ground into a fine powder using large rotating mills. This powder typically contains less than 1% copper. Depending on the type of ore, sulfide ores are sent to a concentrating stage, while oxide ores are transferred to leaching tanks.

3. Concentrating

The powdered ore undergoes a process that concentrates the minerals into a slurry containing around 15% copper. Waste materials, or slag, are removed, and the water used is recycled. The remaining copper oxide tailings are either sent to leaching tanks or returned to the surrounding environment. Once concentrated, the copper can be processed into pure cathodes through two primary methods: Leaching & Electrowinning or Smelting & Electrolytic Refining.

4. Leaching and Electrowinning (SX/EW)

- Leaching: Oxide ores and tailings are treated with a weak acid solution, which results in a copper sulfate solution.

- Electrowinning (SX/EW): The copper-laden solution is then transferred to an electrolytic tank, where an electrical charge causes pure copper ions to migrate to cathodes made from pure copper foil. This process not only produces high-purity copper but can also recover valuable precious metals from the solution.

Alternative Method: Smelting and Electrolytic Refining

- Smelting: The copper undergoes multiple stages of heating and purifying, transitioning through matte, blister, and finally, 99% pure copper.

- Electrolytic Refining: In this step, the copper anodes are immersed in an acid bath. The electrolysis process allows pure copper ions to migrate to “starter sheets,” eventually building up into pure copper cathodes. Precious metals like gold, silver, and platinum are also extracted from the electrolyte.

5. Pure Copper Cathodes

Once refined, copper cathodes with a purity level of 99.9% are produced. These high-purity cathodes can be shipped as melting stock to mills or foundries for further processing. Alternatively, the cathodes can be cast into different forms, such as wire rods, billets, cakes, or ingots—either as pure copper or in alloyed forms with other metals.

6. Conversion into Final Products

- Wire Rod: The cathodes are drawn into coiled rods of about ½” in diameter, which are then used to produce pure copper wire in various gauges for the electrical and communications industries.

- Billet: Copper cathodes are cast into large, 30-foot logs (approximately 8” in diameter). These billets are cut into shorter lengths, which are then extruded and drawn into tubes, rods, and bars in various shapes and sizes.

- Cake: Slabs of copper, generally around 8” thick and up to 28 feet long, are rolled both hot and cold to produce copper plate, sheet, strip, and foil.

- Ingot: Copper ingots, typically in brick form, are used by mills for alloying with other metals or by foundries for casting purposes.

Frequently Asked Questions (FAQ)

What is the purity level of your copper cathodes?

Our copper cathodes have a purity level of 99.9%, ensuring exceptional performance across various applications.

Where are your copper cathodes sourced?

Our copper cathodes come directly from the Democratic Republic of Congo and are available in Dar es Salam ready to ship.

What is the minimum order quantity (MOQ)?

The minimum order quantity for our copper cathodes is 22 metric tons (MT).

How quickly can you deliver?

We deliver globally within 7-15 days, depending on the destination.

Can I customize the packaging?

Yes, we offer custom packaging solutions to meet your specific needs.

What payment terms do you offer?

Negotiable

Are your copper cathodes eco-friendly?

Yes, we prioritize sustainable practices by sourcing from recyclers, reducing the environmental impact of copper production.

What industries use your copper cathodes?

Our copper cathodes are widely used in:

- Electrical wiring

- Construction

- Automotive manufacturing

- Industrial equipment production

- and various other industries

How long does it take to ship my order?

Shipping times vary based on the destination country. We ensure timely delivery with reliable logistics partners for all international shipments.

Do you offer any discounts for bulk orders?

Yes, we provide competitive pricing for bulk orders. Contact our sales team for more details and customized quotes.

What Our Clients Say – Testimonials from Around the Globe

South Korea

“Tamasha Group has been our go-to supplier for copper cathodes. Their high-quality products and prompt deliveries have exceeded our expectations.”

— Kim Joon-ho, Import Manager, Seoul, South Korea

Japan

“The purity and reliability of Tamasha Group’s copper cathodes are unmatched. We’ve successfully used them in our automotive manufacturing projects.”

— Aiko Tanaka, Purchasing Director, Tokyo, Japan

European Union

“We’ve been importing copper cathodes from Tamasha Group for over two years. Their professionalism and product quality are exceptional.”

— Johann Müller, Operations Head, Munich, Germany

United States

“Tamasha Group is one of the best copper cathode trading companies we’ve worked with. Their products have significantly improved our production process.”

— Michael Thompson, CEO, Chicago, USA

Contact Us to Secure Your Order Today!

At Tamasha Group, we are committed to providing high-quality copper cathodes for sale that meet and exceed your expectations. As trusted supplier of copper cathodes, we ensure seamless transactions, reliable delivery, and excellent customer support.

Get in Touch

📍 Location: Block Number 46, Streeniat Mbezi Beach Makunde, Dar Es Salaam – Tanzania

📞 Phone: +255 767 647 642

📧 Email: contact@tamashagroupofcompanies.com

Secure your supply of high-purity copper cathodes today and partner with one of the best supplier of copper cathodes in Tanzania! Experience the TAMASHA difference for yourself.